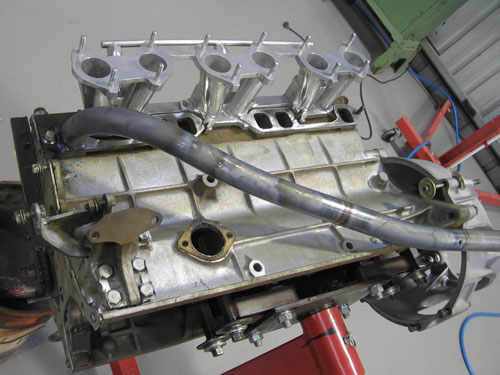

Making the head flange, custom matched to ports

1st pipe done

2nd pipe done

Back in car to check

Starting pipe 4

Pipe 4 taking shape

Good steel makes great colours when hot!

Pipe 4 nearly done

Always carefully checking lengths

5 pipes all OK in the car

6 pipes all pointing in the right direction

All 6 pipes checked in car

…and undernearth

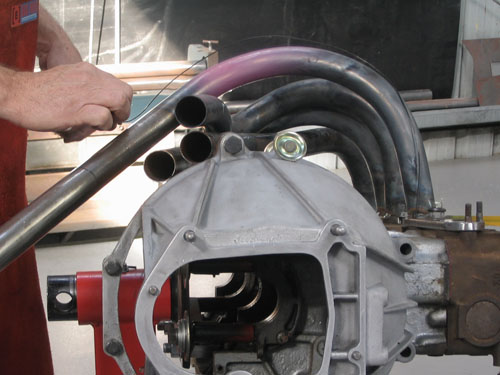

And now to build the collector

Collector set stage 2

Collector complete

Prince pipes collected

Collector fitted and checked in car

ready for polishing

Polished Price Pipes – ready to bolt on

Building exhaust extractors is a science, and also an art. Mastering the science involves understanding the effect pulse waves have inside an exhaust manifold and in how to use this effect to boost the flow. The art, I think, is self evident when one looks at the finished product.

Extractors can be constructed by either sand bending pipes to the shapes required, as shown in the images at left, or by cutting and joining pieces of mandrel-bent pipe, as shown in the photo below. This latter method becomes the only choice for large diameter extractors that need to fit into a tight space.

At the design stage, pipe diameter, primary pipe length and, if used, secondary pipe length are critical specs. During construction, port matching and pipe length matching are crucial to a quality, optimum performing component.